The cementmaking process, from crushing and grinding of raw materials, through roasting of the ground and mixed ingredients, to final cooling and storing of the ...

Loesche Mills for cement raw material. 2 Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second ...

CEMENT RAW MATERIALS PLANT SIZES. The coordinates of the grinding table diameter and number of rollers can be read off from the table. The x .

Drying of raw material may also be necessary for efficient crushing and preblending 3. ... Finish milling is the grinding together of cement clinker, ...

3 These differences between cement grinding and grinding of raw materials made it a serious challenge to obtain a good performance of a vertical roller mill in cement .

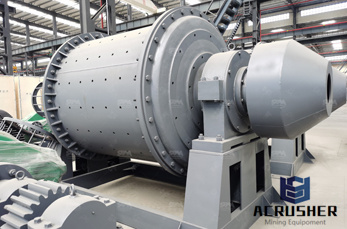

Cement Ball MillThe ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry ...

Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones ...

Grinding occurs at the beginning and the end of the cement making process. Approximately tonnes of raw materials are required to produce 1 tonne of finished

cement raw material grinding cement raw material grinding,raw milling cement,unityitin Cement GrindingVRM or Ball,_ Whilst it .

How we make cement Titan raw material grinding cement,The raw materials for cement production are mined by the use of explosives (drilling blasting) or by ...

Finished cement is produced by finely grinding together around 95% cement ... The raw materials used in cement manufacture are extracted in large quarries, typically

The raw materials are extracted from the storage silos via weighfeeders. The materials are conveyed to the grinding mill and are ground to a suitable fineness ...

Know More ... raw grinding in cement industry Joyal Cement Materials industry,limestone Powder Grinding Plant Limestone powder as a main raw material in the cement ...

Cement Grinding Mill It is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement ...

Portland cement is the most common type of cement in general use around the world as a basic ... the ash of the coal acts as a secondary raw material. Cement grinding ...

Raw material mill products are mainly used for grinding of cement raw materials, also applies to the metallurgical, chemical, electric power and other industrial and ...

raw material grinding cement industry; raw material grinding in a cement plant . Ukrainian cement plants. In the cement industry used different grinding schemes ...

275 Cement Manufacturing Industry Description and Practices The preparation of cement involves mining; crushing, and grinding of raw materials (princi

Learn cement manufacturing process ... setting or ordinary or Portland cement: Mixing of raw materials ... a result of the grinding in the raw mill is ...

Cement Manufacturing Technologies In cement mining, you need to choose suitable cement grinding mill and cement crusher. Primary Crushing Secondary Crushing; Pre ...

Aug 26, 2016· Raw material grinding in a cement plant, Grinding Mill China Raw material grinding is a critical mechanical operation determining the sizing of ...

raw material used for making cement clinker. in which material ingredient cement making | mining company Price making cement. smaller raw materials used cement .

Raw Material Grinding Cement. ... Chemical analysis was also performed to determine the chemical composition of ash and individual raw material for cement design.

Portland Cement Manufacturing Process Description17 ... In the wet process, water is added to the raw mill during the grinding of the raw materials in

WhatsApp)

WhatsApp)